Ferrovial improves heavy construction efficiency with ConnectedWorks

December 26, 2025

"With ConnectedWorks, you just have to open the platform to see if a team has more trucks than necessary, if the average speed on a section is unusually low, or if there are prolonged wait times in a specific area. Everything is extremely transparent."

Ignacio Tejeda, Head of Production at Ferrovial Construction

Real Efficiency in Earthmoving Thanks to IoT and AI

In the early hours of the morning, when a high-speed rail construction site wakes up, everything moves fast. Trucks line up waiting for their turn, excavators roar, production managers exchange instructions over the radio, and every decision made—or not made in time—translates into minutes lost or millions of euros saved.

In this demanding scenario, where every cubic meter of earth moved is money and every unnecessary wait is a silent cost, the question is almost inevitable: How do we know in real-time if all that ballet of machinery is really working to its full potential?

Until very recently, the answer was frustrating. We didn't know. The site manager relied on phone calls, messages exchanged between foremen, and intuition. There were basic geolocation tools, but they provided no useful information to understand the actual work cycle. When does each truck load? How long does it take to unload? How many trips does it actually make? How long is it idle and why?

There was no data. There was no visibility. And without visibility, there was no optimization.

The Reality of a Giant, Low-Visibility Problem

On a linear construction site spanning several kilometers, earthmoving represents a significant percentage of the investment budget. For companies like Ferrovial Construction, optimizing it can mean millions of euros in savings and finishing days ahead of schedule. However, although technology had already transformed other phases of construction—design, planning, certifications—this part remained practically blind.

It wasn't for lack of trying: existing systems were based on simple GPS to know "where the trucks are," but said nothing about their actual performance. And the complexity of these projects, combining owned and subcontracted machinery, different types of vehicles, and routes on uneven terrain, complicated the equation even further.

The result: a chain of late and reactive decisions, hard-to-detect downtime, and poorly sized resources. The need was evident, but no one had managed to solve it with a truly practical, economical, and scalable solution.

The Question That Changed Everything

In late 2018, at the Ferrovial Digital Hub, a key question was raised: How could we know at all times what happens in the earthmoving production cycle, without complicating life for those in the field?

The answer didn't come from a traditional vendor, but from a mixed team of Ferrovial engineers and IoT experts from Sngular, accustomed to developing custom solutions for complex challenges. Together, they understood that the key wasn't just putting a GPS on a truck, but capturing behavioral patterns with smart sensors and processing them with algorithms capable of turning vibrations and movements into readable data.

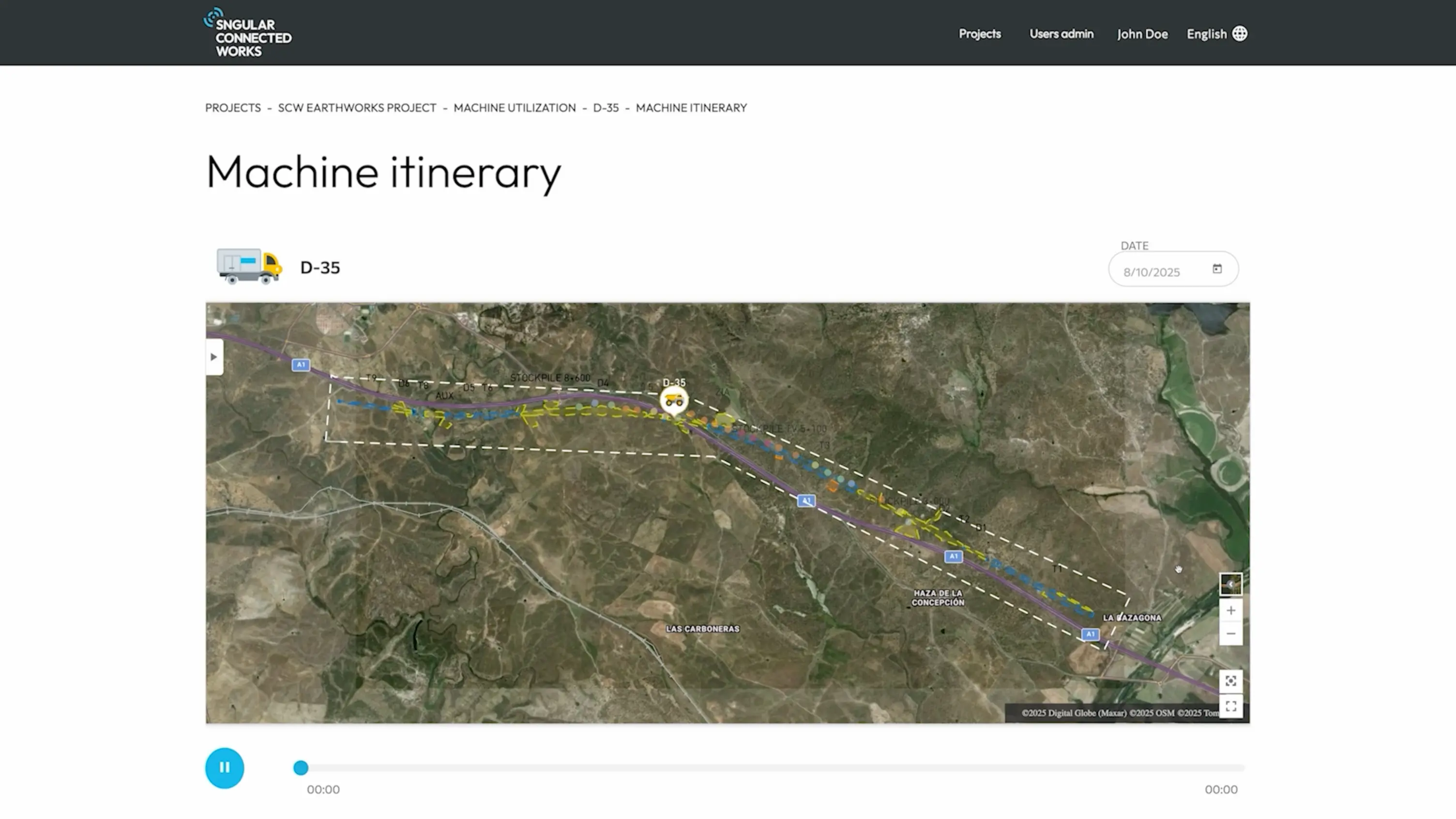

Thus was born the idea of ConnectedWorks, a solution featuring an autonomous, cost-effective, wireless device that is easy to install on any dump truck. This device is capable of automatically detecting when a truck is loading, transporting, and unloading, thanks to a gyroscope, accelerometer, GPS, and vibration sensors. It has internal memory to function without network coverage and a battery to ensure its independence.

But above all, what makes this platform special are its advanced AI-assisted algorithms. These analyze production cycles in real-time, allowing inefficiencies to be identified and information to be returned to site teams in a clear and actionable way.

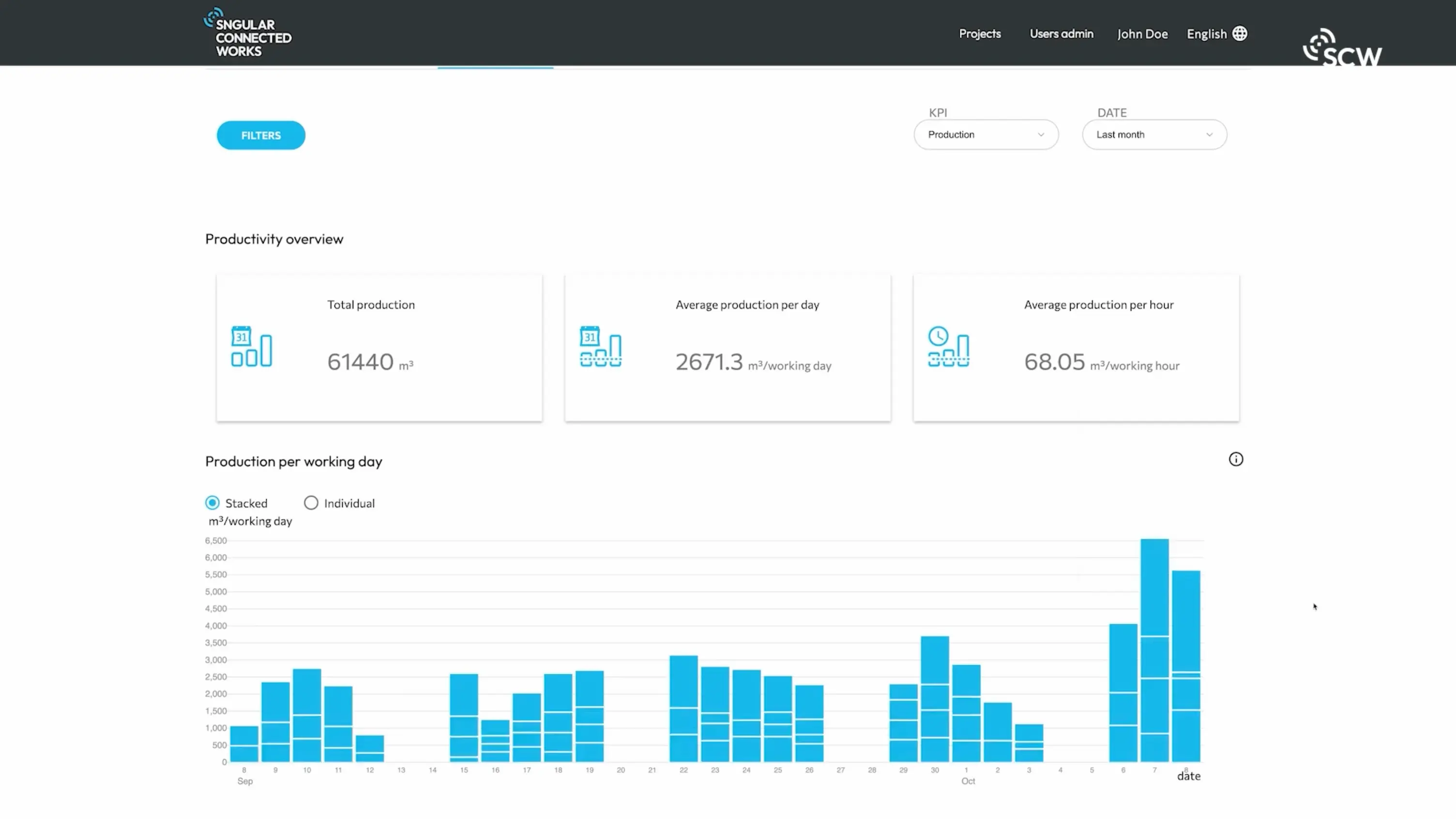

All this technology enables an interactive dashboard with site maps, KML plans, loading and unloading zones, drone integration for orthophotos, and real-time alert functionalities. Furthermore, it adapts to the hierarchy and profiles of each project, with different roles and permissions so that information flows but remains protected.

From Prototype to Field: A Collaborative Challenge

However, no technology is here to stay if it doesn't solve real frictions. The ConnectedWorks team soon understood that success didn't depend only on the hardware or the algorithm, but on the acceptance of the people who have to use it every day.

A linear high-speed rail project, for example, can involve dozens or even hundreds of trucks from different sources. Some belong to the construction company, others are subcontracted to local companies that rotate from one project to another. And every truck has its peculiarities: new models with modern electronics, older vehicles without standardized power outlets, and operators who, understandably, distrust anything they perceive as excessive control over their work.

The device design responded directly to that reality. Installation is quick, with a magnetic system that allows it to be attached to the truck bed in minutes and removed just as easily when the shift ends or when that truck changes sites. No visible cables, no drilling, no need to modify the vehicle. If a truck is rented for a short period, the device can be dismounted and placed on another. This operational flexibility is one of the reasons ConnectedWorks has overcome a key barrier: the variety of the machinery fleet.

But human acceptance doesn't just depend on technical ease. From the beginning, Sngular bet on a co-creation strategy together with the site teams. Each iteration was validated with the operators and production managers themselves, listening to practical suggestions ranging from the size of the device to how information is presented on the dashboard.

From that close relationship, a lesson emerged: data, on its own, changes nothing if it isn't understandable. That's why the platform accompanying the hardware has been refined so that anyone, even with little digital familiarity, can quickly understand what is happening in their work zone without depending on a data analyst.

The result is a system that feels like a useful tool—which also adds safety for machinery operators—rather than a burden. Testimonies from the teams themselves confirm this: when they see that the information helps them solve real problems—from relocating trucks to balance loads to planning more efficient routes—adoption stops being an imposition and becomes a way of working.

When Data Becomes Decisions

As ConnectedWorks was deployed across different sites, the conversation about efficiency began to change. What was previously discussed based on assumptions and impromptu meetings next to trucks is now backed by precise information. For site managers, the day no longer ends with a simple estimated calculation of cubic meters transported. It ends with a real, verifiable, and detailed report of how many trips each vehicle made, how much time it was actually working, and where bottlenecks occurred.

This ability to see what is happening almost live transformed something deeper than numbers: the work culture. Teams began to internalize that, thanks to this data, they could anticipate problems that were previously normalized. An excavator stopped for half an hour because it doesn't have enough trucks to unload earth is no longer just a field anecdote. Now it is identified, measured, and solved.

Ignacio Tejeda, Head of Production at Ferrovial Construction, explains it with the calmness of someone who has lived through projects where every minute of delay comes at a high price. "Previously, an unplanned stop or a detour was enough to throw the whole chain off balance. The only way to know was when trucks started queuing up or the daily production numbers didn't add up," he relates. "Now, with ConnectedWorks, you just have to open the platform to see if a team has more trucks than necessary, if the average speed on a section is unusually low, or if there are prolonged wait times in a specific area. Everything is extremely transparent." Everything is there, without the need to saturate foremen with calls or travel kilometers to check in person.

Efficiency Measured Every Day

The benefits of ConnectedWorks are as measurable as the kilometers traveled by the trucks that have it installed. According to Alejandro Pérez, CEO of ConnectedWorks, "in high-speed rail projects, where earth movements are colossal, reductions of up to 20% in machinery wait times have been recorded. In practice, this means excavators and trucks are working for more productive time and spending less time idle. In turn, this allows for better resource redistribution, optimizing fleet usage, and consequently reducing the need to rent additional machinery or extend shifts unnecessarily."

The impact isn't limited to numbers. There is a less visible but equally important effect: the reduction of operational stress. Knowing with certainty what is happening on each work front, and having the ability to react without waiting for problems to worsen, gives field managers back a measure of control that, in such dynamic projects, had always slipped through their fingers.

Interestingly, this mindset shift doesn't just impact operations. It is also noticeable in relationships with suppliers and subcontractors. According to Ignacio Tejeda, "by having objective data, conversations regarding billing and distance certification become clearer, less subject to argument, and with less room for discrepancies. The actual kilometers transported are recorded, with their time and coordinates. For all actors in the chain—main contractor, machinery subcontractors, and truck providers—this reduces uncertainty and strengthens trust."

For large construction companies, having a solid history of production cycles is a differential advantage against competitors who continue to manage part of these operations by eye. Return on investment is measured not only in immediate operational savings but also in the ability to improve the profitability of future projects.

The Leap from Rail to New International Horizons

ConnectedWorks was born to answer a very specific need in large-scale linear railway projects, but its applicability has proven to be much broader.

Today, the solution has been deployed in environments as diverse as highways, or operations in deserts where network coverage is limited and reliance on local subcontractors is high. Results obtained in places as diverse as the Atacama Desert, the Canary Islands, or the HS2 line between London and Birmingham—considered the largest civil engineering project in Europe—confirm that the combination of autonomous hardware and intelligent data processing works in almost any environment where earth is moved on a large scale.

The natural next step is to expand this logic to other sectors. Mining, for example, shares many of the logistical challenges of a railway project: large volumes of material, variable routes, vehicles from different sources, and environments combining owned and external machinery. In intensive agriculture, the idea of monitoring production cycles is also gaining ground to optimize transport routes for organic matter or waste. Even in the management of rubble or heavy industrial waste, movement traceability translates into economic savings and greater sustainability.

In all of them, the question is the same: How can we turn every machine into an information node that helps us work better, faster, and with less waste?

What started as a specific solution has become an adaptable technological platform, designed to grow hand-in-hand with each sector. The key is the same: real data, intelligent algorithms, and a visualization layer that turns technical complexity into clear information for those who must make decisions on the ground.

And ConnectedWorks is not a closed solution, but a living technology that grows alongside those who use it in the most demanding terrains.

An Open Roadmap

The ConnectedWorks team knows the road doesn't end here. The solution continues to evolve, integrating new features that make it increasingly complete. Integration with drone imagery to update site orthophotos in real-time, the incorporation of AI layers to predict incidents before they happen, or the possibility of crossing data with other BIM management systems are already on the table.

The medium-term vision is clear: "ConnectedWorks aspires to become a standard for any company managing massive material movements, regardless of whether it's a railway, a mining operation, or a large agricultural estate. The logic is always the same: what gets measured gets improved, and what gets improved becomes a competitive advantage," states Alejandro Pérez.

When Innovation Leaves a Real Mark

In a sector where the word "innovation" has been used so many times that it sometimes loses weight, ConnectedWorks demonstrates that the difference lies not in technology alone, but in how it is placed at the service of those who actually move the earth. The solution was born from an urgent need, refined by listening to every detail of the field teams' day-to-day lives, and validated in some of the most complex environments in the world.

Today, its greatest achievement isn't just reducing downtime or optimizing routes: it is having opened a new way of understanding efficiency. A way that, instead of imposing technology from an office, is built on the construction site, where every minute counts and every data-driven decision turns into well-invested cubic meters.

The future of heavy construction, mining, or waste management will belong to those who understand that data isn't a report at the end of the month, but a living tool for making better decisions every day. ConnectedWorks has proven this with figures, with testimonies, and, above all, with a philosophy that leaves a mark where it matters most: on the earth that is moved, in the resources saved, and on the people who keep everything moving forward.

Our latest news

Interested in learning more about how we are constantly adapting to the new digital frontier?

Insight

February 9, 2026

How the new LLMs hosted on Atlassian work: a guide for companies seeking secure AI

Insight

February 5, 2026

Infinite Worlds: When the best graphic is your imagination

Insight

December 15, 2025

How to use Rovo in Confluence: Guide to creating content with AI