Generative AI rewrites the rules of scientific discovery at Repsol Technology Labs

July 1, 2025

From years to days. Unveiling the secrets of matter at record speed

The story of humankind is deeply interwoven with the mastery and transformation of materials. Each stage of our development as a civilization has been marked by our ability to discover, shape, and harness new substances. From the Stone Age — when flint knapping enabled the creation of primitive tools and weapons, forever changing humanity’s relationship with its environment — to the Metal Ages, which brought the smelting of copper, bronze, and later iron, exponentially expanding our technical, military, and architectural capabilities.

Even materials that are commonplace today, like aluminum, were once symbols of exclusivity and progress. In the mid-19th century, during the reign of Napoleon III, aluminum was more valuable than gold, reserved for imperial tableware and scientific exhibitions. This pattern repeats itself over and over again; materials we now consider trivial were once revolutionary. Teflon, for example — the polymer coating millions of frying pans in kitchens worldwide — was discovered by accident in 1938 when a DuPont chemist was researching refrigerants. What began as a fortunate accident ended up transforming an entire industry.

Materials science in the face of a global crisis

Relying on intuition, serendipity, or trial and error as the primary engines of material discovery is a luxury humanity can no longer afford. Today’s challenges — from the climate crisis and scarcity of natural resources to space exploration and the urgent need for advanced medical solutions at ever-increasing speeds — demand a radically different approach: more systematic, faster, and more precise.

At the Repsol Technology Lab, this urgency translates into concrete goals, like the transition to a more sustainable energy model. According to José Miguel Seoane, Technology Advisor at Repsol, “one of our main challenges is to achieve the mass and cost-effective production of green hydrogen, a clean, versatile energy carrier that is fundamental for decarbonizing sectors that are difficult to electrify.” However, producing it efficiently — especially from abundant resources like seawater — requires a crucial breakthrough: the development of new catalysts that overcome the limitations of current ones, which often depend on precious, scarce, and expensive metals.

"This is why we need significantly more efficient, durable, and affordable materials to make green hydrogen truly scalable and viable globally”, says Seoane.

However, the space of theoretically possible materials is overwhelming. It is estimated that there are between 10¹⁰ and 10⁶⁰ stable combinations of elements. For perspective, the number of atoms in the observable universe is estimated to be about 10⁸⁰. Out of that vastness, humanity has characterized only a few million compounds — approximately 10⁶. Clearly, we have barely scratched the surface.

The paradigm shift

This is where a new scientific frontier emerges, powered by generative artificial intelligence, quantum simulations, and large-scale cloud computing — which is revolutionizing not only chemistry but multiple scientific fields.

For over 50 years, predicting the three-dimensional structure of proteins from their linear amino acid sequence was unsolvable by conventional methods, even with the help of computational tools. This 3D structure determines a protein’s function — if it folds incorrectly, it often fails to function, causing disease. The problem is that there is an astronomical number of possible ways a protein can fold.

Enter AlphaFold, developed by DeepMind, Google’s R&D lab. AlphaFold solves this problem with unprecedented accuracy, reaching results comparable to experimental lab methods — such as X-ray crystallography or cryo-electron microscopy — which are much slower and more expensive. In 2020, AlphaFold 2 revolutionized biology by predicting structures with high accuracy in minutes, creating a free database of more than 200 million proteins. In 2024, AlphaFold 3 expanded this capability to predict how proteins interact with other molecules like DNA and RNA.

This advance accelerates biomedical research and drug development. In fact, for this pioneering work in protein prediction and design, AlphaFold was awarded the 2024 Nobel Prize in Chemistry.

While AlphaFold focuses on proteins, GNoME (Graphical Networks for Materials Exploration) does the same for the inorganic world.

This leap is not just quantitative. Among the newly discovered compounds are more than 52,000 layered materials — two-dimensional structures with properties similar to, and sometimes surpassing, graphene — multiplying by fifty the number of known materials of this type. Additionally, 528 potential lithium-ion conductors have been identified, expanding the known variety by twenty-five times, with a huge potential impact on developing more efficient, lighter, and longer-lasting batteries.

As Javier García-Lasheras, SVP DeepTech at Sngular, explains, “this revolution not only accelerates the discovery process but transforms it at its core. It’s no longer just about experimenting in physical labs but modeling molecular behaviors, predicting properties before synthesizing a single compound, and exploring millions of combinations in search of optimal solutions.” We are thus entering a new era: the Age of Smart Materials.

An era in which knowledge is accelerated, where each atom can be simulated, adjusted, and optimized before it even exists. Chance has given way to directed design. Intuition is reinforced — or even surpassed — by algorithms capable of learning from nature, exploring spaces impossible for humans, and suggesting entirely new structures. And time, that scarce resource, can be compressed thanks to platforms that process complex models in days instead of years.

From left to right: Israel Olalla, Cloud Customer Engineer Manager at Google Cloud; José Miguel Seoane, Technology Advisor at Repsol Tech Lab; and Javier García-Lasheras, SVP of Deep Tech at Sngular, during the Google Cloud Summit 2025.

How does GenAI achieve such a feat?

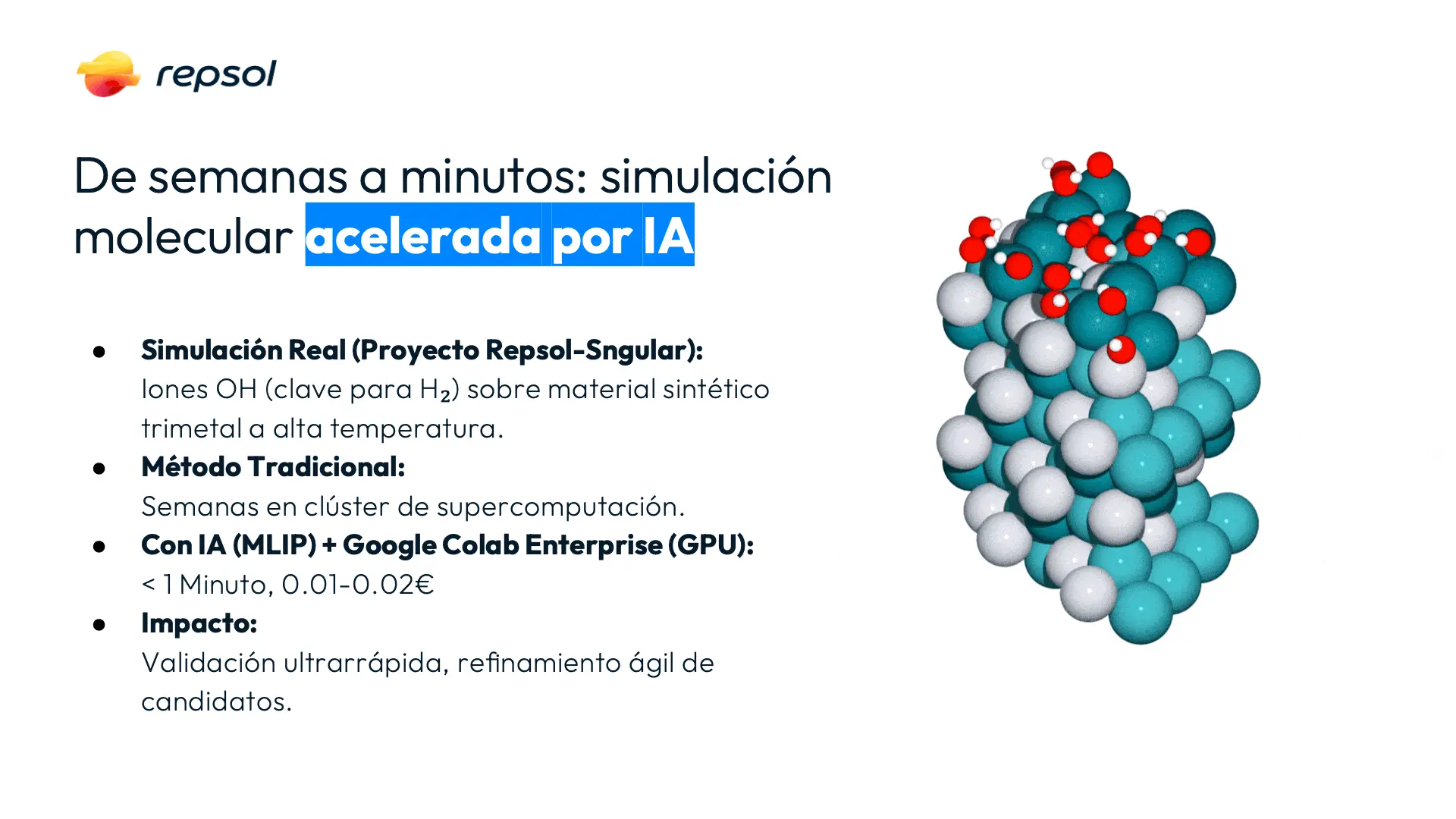

Within the joint project between Sngular and Repsol Technology Lab, this technology is being used, for example, to model the interaction of hydroxyl ions with the surface of a synthetic trimetallic crystal at high temperatures — a representative scenario of key catalytic processes for green hydrogen production.

The process combines physics, data, and deep learning in an unprecedented synergy. Instead of calculating every possible atomic configuration from scratch using classical methods — extremely precise but also slow and costly — artificial intelligence can “learn” the fundamental principles governing interactions between atoms and how these interactions give rise to a material’s macroscopic properties.

This learning feeds on massive amounts of data. These data can come from quantum mechanical simulations — highly precise but very slow — or existing experimental databases. The AI digests this information and builds an internal “knowledge map”, faithfully capturing the forces acting at the atomic level and reasoning about real-world elements.

Once these underlying rules are established, AI can do two extraordinary things. First, it can predict the behavior of candidate materials in milliseconds, with an accuracy comparable to traditional methods but at speeds millions of times faster. This allows researchers to navigate vast materials design spaces in previously unthinkable timeframes and costs.

But the true magic of Generative AI goes beyond prediction; it can also propose completely new material structures (hence the term “generative”). “It’s like a musical composer who, after studying all the works of Mozart, Bach, and Beethoven, can not only identify their style but compose a new symphony that sounds authentically classical yet original. Generative AI can suggest combinations of elements and crystal structures that no scientist might have imagined, optimized for the properties we seek,” says García-Lasheras.

Simulations of this complexity using a supercomputing cluster would take years of work. Now, thanks to interatomic potentials developed with Machine Learning (MLIPs) and inference executed on an optimized, cost-efficient CPU/GPU/TPU instance in Google Colab Enterprise, this is reduced to days. This drastic reduction allows exploration of endless possibilities previously out of reach due to economic and time constraints, making it part of any scientific team’s daily work.

This advance not only enables faster hypothesis validation but transforms everything. Now it is possible to generate thousands of scenarios, iterate designs in real time, and explore compositions once deemed impossible, radically accelerating the path from idea to functional prototype.

AI + Expertise + Robotics

In this new paradigm, generative artificial intelligence does not replace human knowledge; it amplifies it. As Seoane says, “this revolution is not about replacing researchers but freeing them from repetitive tasks so they can focus on strategic decisions and creative thinking. It’s not about handing the scientific process over to algorithms but about establishing a new way of collaborating among AI, human expertise, and automation.”

This new workflow can be understood as a triple alliance, as applied in Repsol Technology Labs: Artificial intelligence, human expertise, and robotics. AI acts as an tireless explorer, capable of generating and evaluating millions of combinations in search of new material structures with desired properties. But its results are not absolute truths; they are highly informed predictions that require validation and expert judgment.

This is where the insight of trained scientists comes in — professionals in chemistry, physics, or materials engineering who bring what AI still cannot replicate: contextual knowledge, practical understanding, sensitivity to real-world limitations, and the ability to interpret results critically. They define the problem, filter out unfeasible proposals for reasons such as toxicity, synthesis costs, or instability under real conditions, and make the decisions that guide the process. AI does not replace their judgment; it strengthens it.

The third pillar of this alliance is robotic automation, especially relevant for experimental validation. Traditionally, synthesizing and characterizing a new material could take weeks or even months. When AI models generate hundreds of potential candidates, the next big challenge is testing them efficiently. This is where autonomous labs or self-driving labs come into play — robotic platforms capable of continuous operation, automating synthesis, testing, and large-scale data collection.

The most powerful aspect of this approach is its ability for continuous learning. The data generated experimentally by these systems not only verify predictions but feed back into the AI models, improving their accuracy and making them increasingly robust. This creates a virtuous circle of prediction, experimentation, and feedback, where each iteration is faster and more effective than the last.

Impact, vision, and the road ahead

Collaboration on this project has confirmed something fundamental: designing new materials driven by artificial intelligence and orchestrated from the cloud is no longer a futuristic idea but a tangible reality. This technical validation demonstrates that we are witnessing a paradigm shift in how research, experimentation, and innovation are conducted.

At Sngular, the approach has been clear: to support organizations like Repsol Technology Lab in adopting emerging technologies — such as generative AI, quantum simulation applied to chemistry, or workload optimization on infrastructures like Google Cloud — and turning all that potential into practical, scalable solutions with real impact. Transformation is not just about technology; it’s about knowing how to integrate it effectively into existing processes.

One of the most significant benefits is AI’s ability to detect patterns and relationships that previously went unnoticed. This not only accelerates the development of materials for known applications — like the catalysts needed to produce green hydrogen — but also opens the door to discovering unexpected properties or even identifying entirely new classes of materials. We are accessing territories that, until recently, we didn’t even know existed.

The potential impact of this transformation is enormous. Cutting the development time for a new catalyst from a decade to just two or three years — or even less — could completely change the economics of green hydrogen. Making these technologies faster, more affordable, and more accessible would have multiplying effects on the global energy transition. And this is just one use case. Applications extend to fields as diverse as direct carbon capture, water desalination, personalized medical devices, or developing advanced materials for more sustainable agriculture. The global challenges that depend on discovering new materials are countless.

In this context, collaboration becomes essential. No single entity can lead this transformation alone. It requires combining multiple capabilities: the deep understanding of industrial and scientific challenges from labs like Repsol Technology Lab; the AI, modeling, and technological architecture expertise provided by companies like Sngular; and the access to cutting-edge computing platforms and innovation offered by players like Google. Only through these interconnected ecosystems can we scale these types of solutions.

Looking to the future, we envision a scenario where materials design becomes a much more predictive, agile, and specific discipline. A context where it will be possible to conceive “on-demand” materials, designed from the start to solve specific problems, just as we now design chips or software for particular tasks. This capability will profoundly transform how we innovate and mark a turning point in how we tackle the great scientific, industrial, and environmental challenges of our time.

Can you imagine bringing this potential to your organization?

The combination of generative artificial intelligence, automation, advanced simulation, and cloud computing is already transforming how new materials are discovered — but its impact goes far beyond that. This is what we call deeptech: applying disruptive technologies to solve complex challenges in energy, healthcare, industry, biotechnology, agriculture, or any field where cutting-edge science and engineering become a true competitive advantage.

At Sngular, we help companies, R&D centers, and technical teams navigate this journey — from the early exploration of technologies and use case design, to the integration of AI models, scalable cloud environments, and process automation. All of this with a collaborative approach tailored to the unique context and goals of each organization.

If you want to explore how to turn these capabilities into tangible, measurable solutions — whether it’s to accelerate the energy transition, optimize industrial processes, innovate in biomedicine, or open new business lines based on scientific and technological breakthroughs — we’re here to listen and support you.

Contact us and let’s take the next step together to turn complex ideas into real impact.

Our latest news

Interested in learning more about how we are constantly adapting to the new digital frontier?

Tech Insight

May 28, 2025

LLMs, Vibe Coding, and software development

Event

May 26, 2025

Madrid pulses with the new era of Artificial Intelligence at the Google Cloud Summit 2025.

Corporate news

April 22, 2025

Sngular and Fakeeh Care Group join forces to create an AI Center of Excellence in KSA

Insight

April 21, 2025

AB360: A Pioneering Platform of Collaborative Intelligence for Sustainable Building